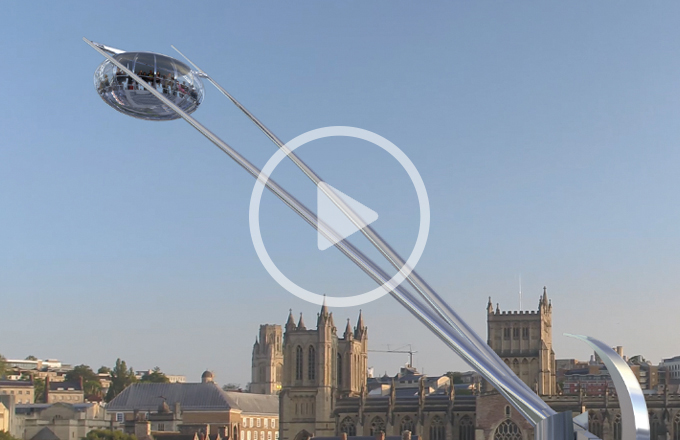

Two masts spanning 55 metres, swinging freely above your head, which at the top are just a bit thicker than a school ruler… perhaps it’s hardly surprising that some people ask, ‘Are you sure Arc’s safe?’

It’s a reasonable question – whether you are in the cabin or walking beneath. How can we know if a design is truly safe before it has been built?

The HSE factor

When planning a large, complex engineering project, there are strict safety guidelines and clear regulatory frameworks in place to which designers must adhere.

Though Arc has not yet been built, there is a method developed by the UK’s Health & Safety Executive to cover it.

‘We have some unusual challenges,’ says Simon Walley, Arc’s Head of Engineering, ‘but the structure, machinery and user experience we are creating all have parallels in other industries. The HSE method requires us to assemble and satisfy an Arc specific set of passenger safety industry standards.’

Weathering a perfect storm

With over 20 years’ experience in the marine industry, including work on the world’s tallest yacht masts, Simon knows that marine safety is more than adequate for Arc’s structure. The construction of Arc’s twin carbon-fibre masts is identical to the large masts used on superyachts – which need to withstand substantial forces at sea way beyond those under which Arc will operate. Carbon fibre is so strong for its weight, it reduces the weight and increased the efficiency of jet flight, keeping millions of passengers safely aloft.

Simon also draws on the design experience of 70-metre wind turbine blades which are now commonplace in offshore wind farms. Standing taller than Arc, the safety of these huge, load-bearing, composite structures is well understood - they are designed to rigorous codes, robustly proven by load tests and monitored throughout their lives by embedded fibre-optic strain gauges. Turbines endure a harsh, salt-water, gale-force environment, and (to disprove the old maxim) are struck by lightning on a regular basis! Carbon fibre is also giving new life to sails on commercial cargo ships to reduce use of marine fuel.

Referencing such technologies gives the confidence that Arc’s twin cantilevered arms will operate safely throughout their design life.

The machinery for Arc is important to its operational safety. Arc will go on if, for example, a motor fails, by switching seamlessly between purposefully doubled-up systems. Despite its superficial resemblance to a huge trebuchet, Arc is always kept in perfect balance – a whopping 100-tonne fan-shaped counterweight at the end of the arms balances the moment of the passengers, cabin and masts, so that, unless powered, the whole assembly won’t move. This ensures a low-energy, smooth ride. Arc uses the same ‘fail-safe’ and ‘mechanical redundancy’ philosophies that have been developed and refined for the aircraft industry over many decades.

Checking for safety won’t only rest with the design team. Arc, like every passenger carrier, must pass (and annually re-pass) rigorous safety third-party assessments on every aspect of safety before it will be approved to carry passengers.

Avoiding ‘high anxiety’

How about user experience? Although our eyes notice speed, we only feel changes in speed, ie acceleration. Well, Arc’s motion is smooth – much smoother than a cable car or moving bus. Arc’s sophisticated motion control will assist the pilot to linger to enjoy the view or rise like an elevator to get you there.

So your Gran could walk the whippet beneath Arc – she will be that safe, certainly.

Whether she’ll go up with you remains to be seen …

Read further:

The Germanisher Lloyd and DNV classification societies have rules for the Design and Construction of Large Modern Yacht Rigs and for Wind Turbine Rotor Blades, whilst fairgrounds and amusement parks are controlled by the 2007 Guidance on Safe Practice. It’s gripping stuff.

▲ Yacht masts on the move